Stocky Pro provides the tools to run your business smarter and more efficiently

Integrated Solutions

Simple yet powerful

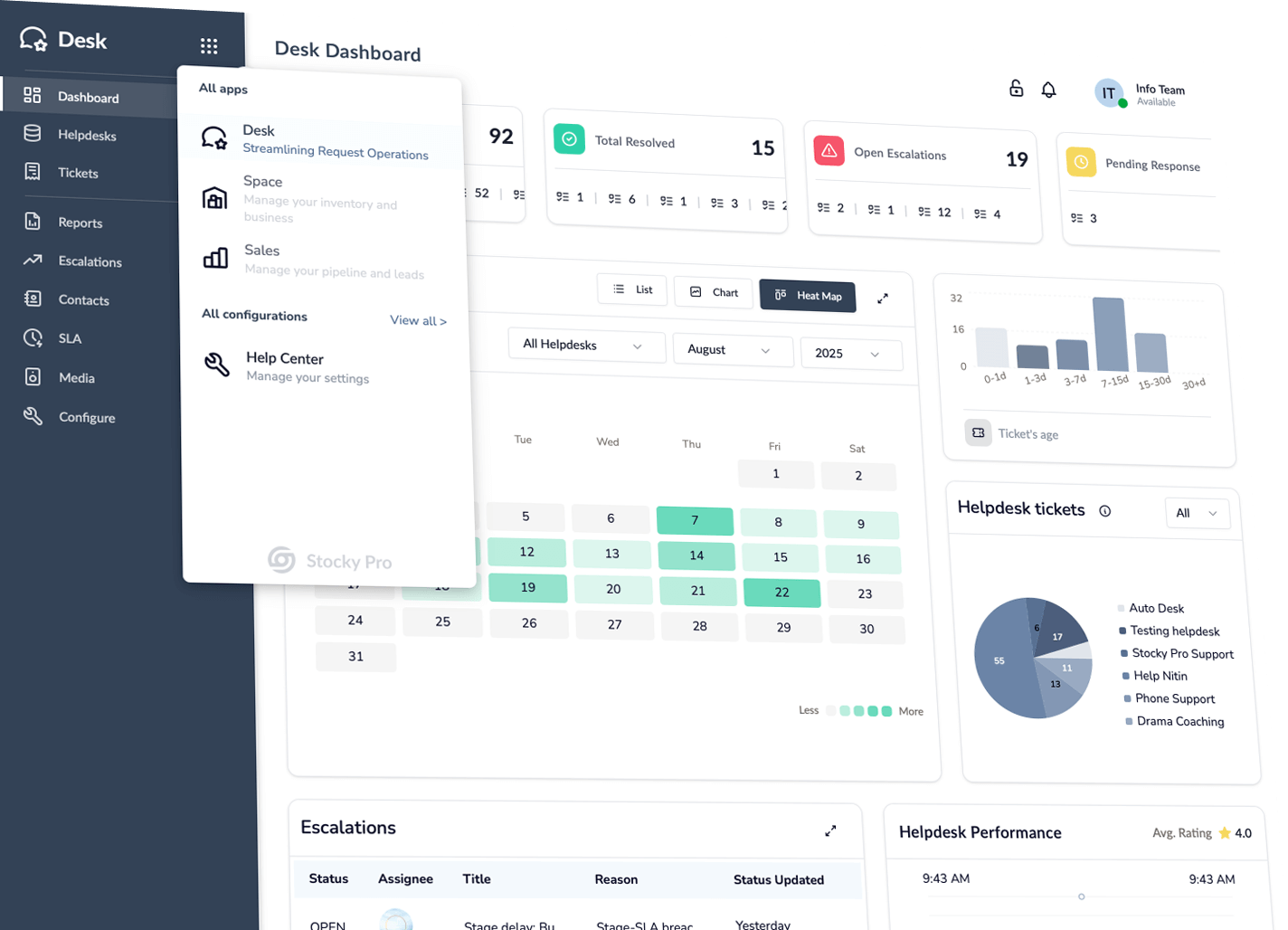

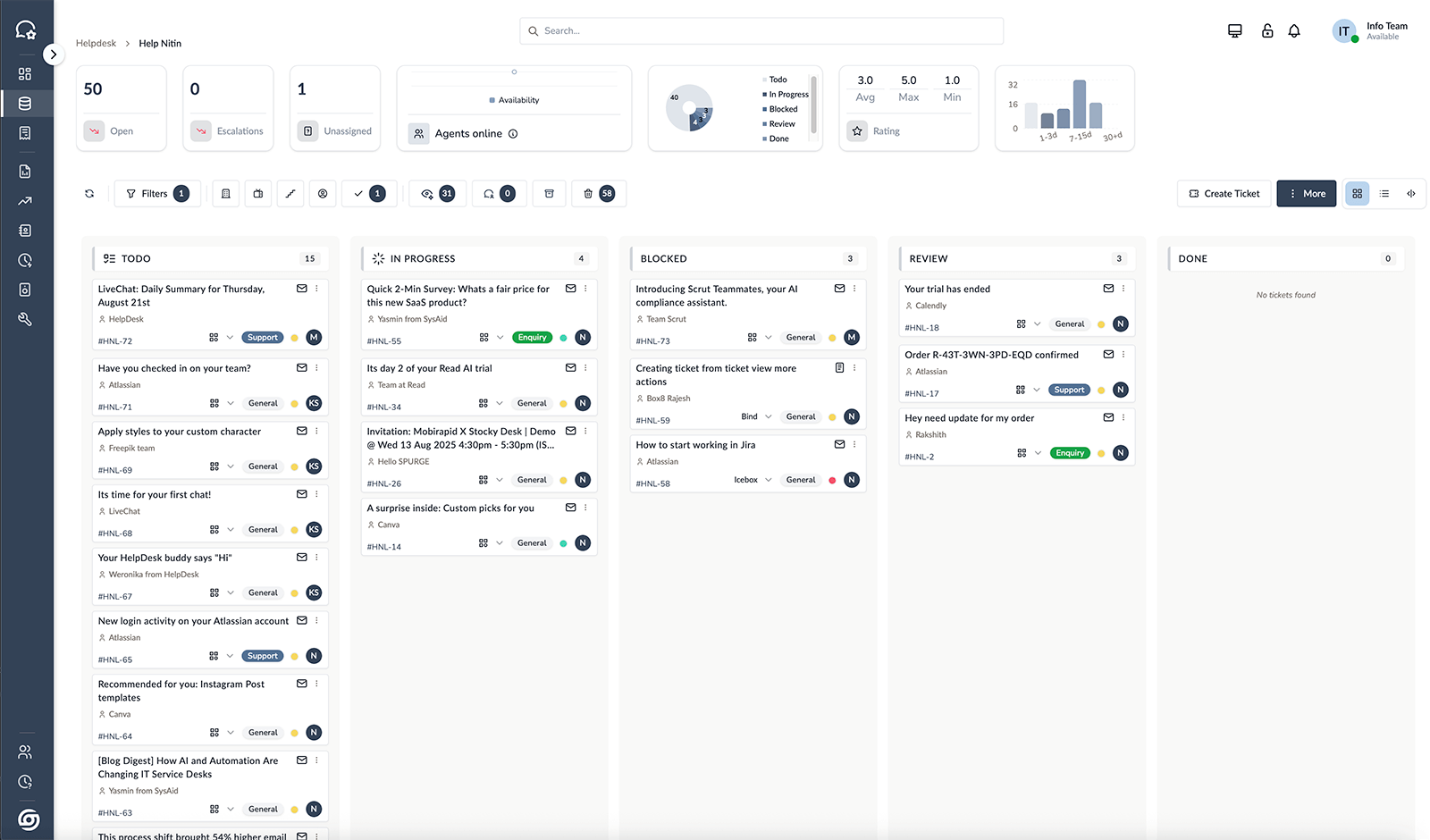

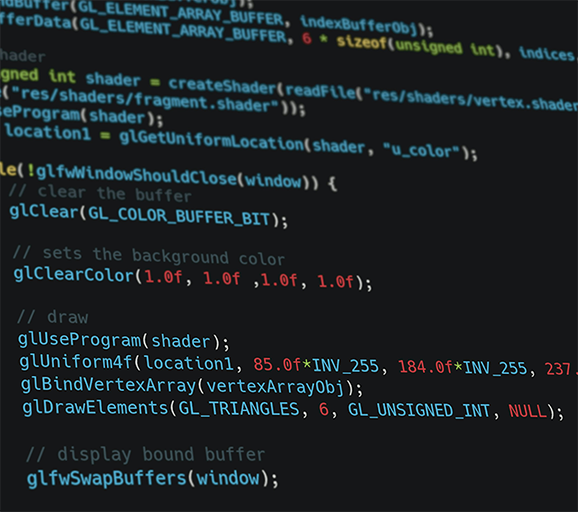

Stocky Desk

All your support in one place—track, assign, resolve—every time.

Stocky Space

See every product’s stage and stock—clear, real-time flow.

Stocky Leads

From lead capture to quotes—AI-ranked and tracked, Multi-pipeline

Stocky Orders

Universal orders: ingest anywhere, track stages live.

Stocky Project Management

Projects, tasks, owners, timelines—status at a glance.

Stocky Assets

Company-wide asset management—track, assign, audit, lifecycle.

Stocky Finance

Universal accounting & finance—billing, invoicing, ledgers, reports.

Stocky Productivity

AI-powered insights into employee efficiency and workflow health.

Stocky HRMS

Universal HRMS—simple yet powerful for people operations.

Stocky Procurement

From request to PO—catalogs, approvals, GRN, 3-way match.

Stocky Contracts

Create, approve, e-sign, renewals & reminders.

Stocky MDM

Endpoint device management—laptops, mobiles, and other devices.

Glimpse of the Apps

One simple suite for ops: Desk centralizes support; Space shows product stages & stock; Sales captures and closes deals; Orders unifies service/sales from quote to delivery—live status, owners, SLAs.

Real Intelligence

This gives you control

Stocky Pro is a connected suite for everyday business usecase. Each module solves real problems with automation, in-house AI (we don’t train on your data), and a simple, reliable UI. No third-party services power our core. From startup to enterprise, run complex workflows easily.

Mission and Vision

operating system for businesses

A decade in business operations

We’ve worked with 1,000+ companies and seen inefficiency, leaks, and common day-to-day operational problems.

A decade building scalable software

We’ve built complex solutions for over a decade, using a scalable approach that grows with your business.

Designed with love

Secure & compliant

Dedicated per-account DB

Your own encrypted database and datastore, isolated per account—always.

Region-based clusters

Choose data region; clusters and servers stay where you need them—period.

Auto backup & recovery

Automatic backups, point-in-time restore, and quick recovery built-in.

ISO 27001:2022 listed

ISO 27001:2022 registration tracked and maintained with full transparency.

GDPR-aligned operations

Built to GDPR principles for robust data protection across stack—always.

App & network security

Defense-in-depth on app and network layers, monitored 24/7 with alerts.

Trusted by leading MNCs

Deployed and trusted by global enterprises (MNCs) across globe.

Clear data privacy policy

Clear privacy policy and strict data-handling practices you can trust.

No surprises—all included

No hidden fees; everything in your plan is included, always.

In-house AI, private LLMs

We run in-house AI models and LLMs; your data never trains our models.

No third-party reliance

We rely on no third-party services; we operate the entire stack ourselves.

Easy, open integrations

Connect Stocky to your apps, APIs, and sites with simple, secure hooks.

Built, Not Wrapped

From Scratch, For Impact

We don’t wrap third-party or open-source tools. We design and build Stocky Pro from scratch to solve real problems—without bloat or dependencies. That’s how we deliver deep, direct value. We believe in crafting the best solution; it’s our mission and vision..

What is our mission?

Expanding worldwide to simplify work

Cut noise and busywork across the whole business support to finance so people can focus on real work. Work that’s connected, measurable, and calm software that just works.

Get Stocky Pro Now !

Available on web, Mac, and Windows.

Sign up for a free 30-day trial. We handle setup, config, and support—free forever.